Thanks to the ROLLERI ROBOTIC software, programming is quick and also simplified by the fact that the most important commands have been remote-controlled on the COBOT handle.

Through a start and end point, the COBOT moves through space recognizing sheet deformations without operator programming.

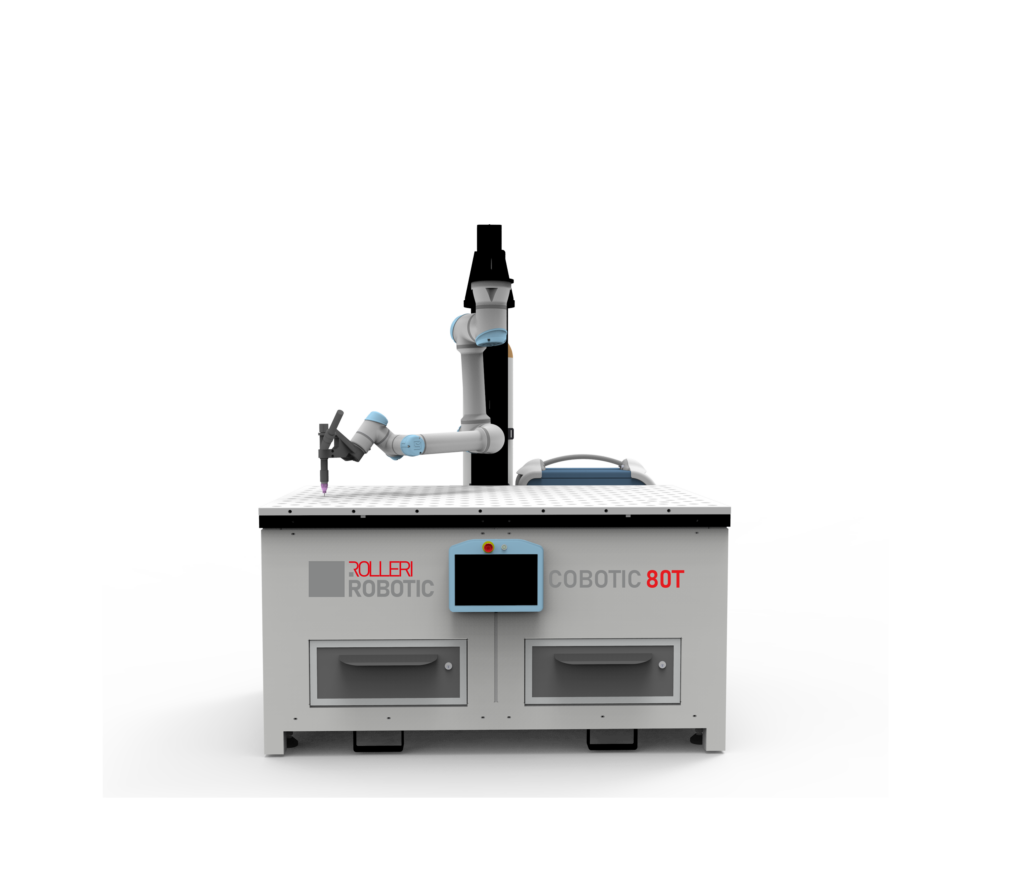

COBOTIC is designed to have a compact volume and limited weight.

It is possible to re-configure the layout of production lines within the work area in an extremely agile way thanks to the provision for forklift or overhead crane pickup.

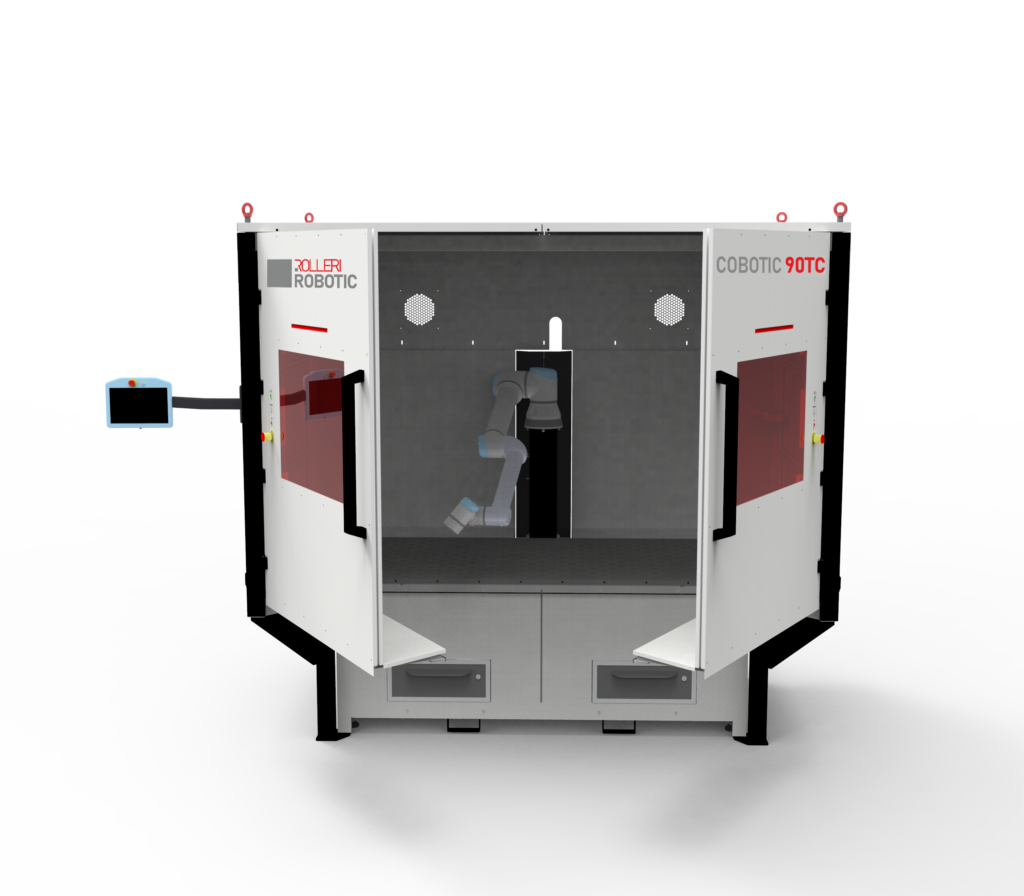

COBOTIC 90TC is used for TIG welding and grinding operations.

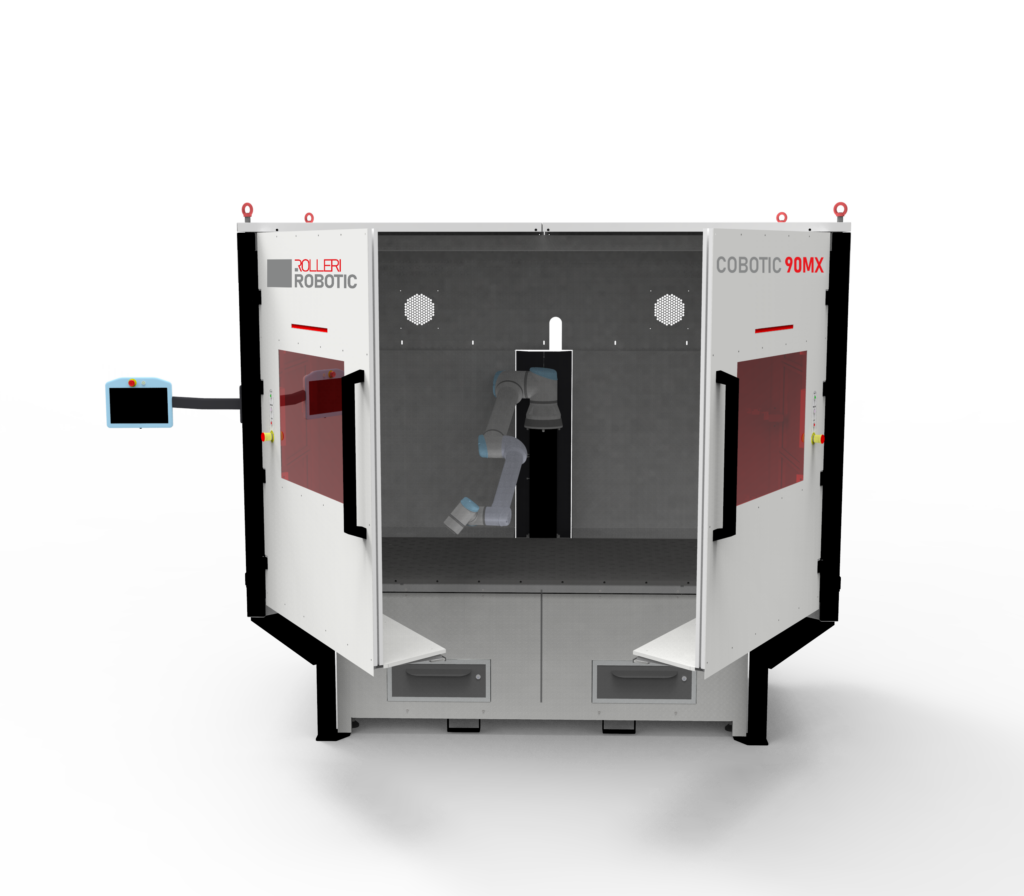

COBOTIC 90MX is used for MIG/MAG welding operations.

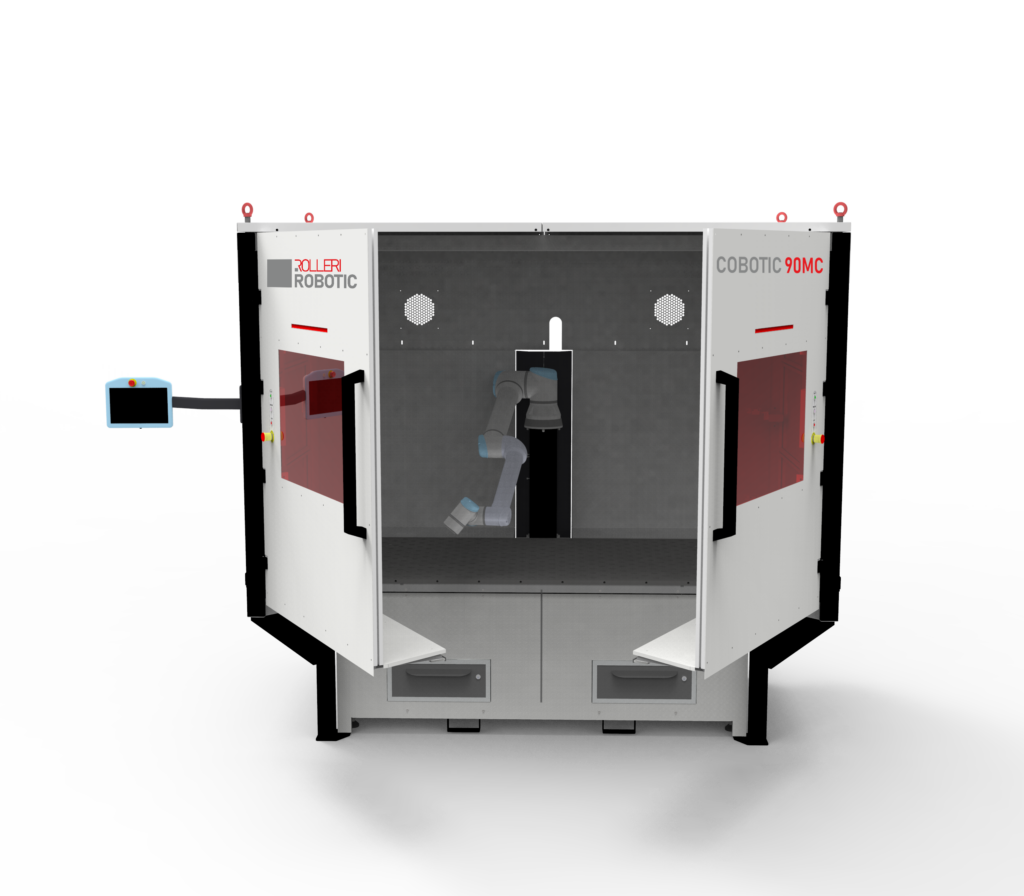

COBOTIC 90MC is used for MIG/MAG welding and grinding operations.

COBOTIC 100M is used for MIG/MAG welding operations.

COBOTIC 80T is used for TIG welding operations.

COBOTIC 100T is used for TIG welding operations.