1. FUNCTIONS

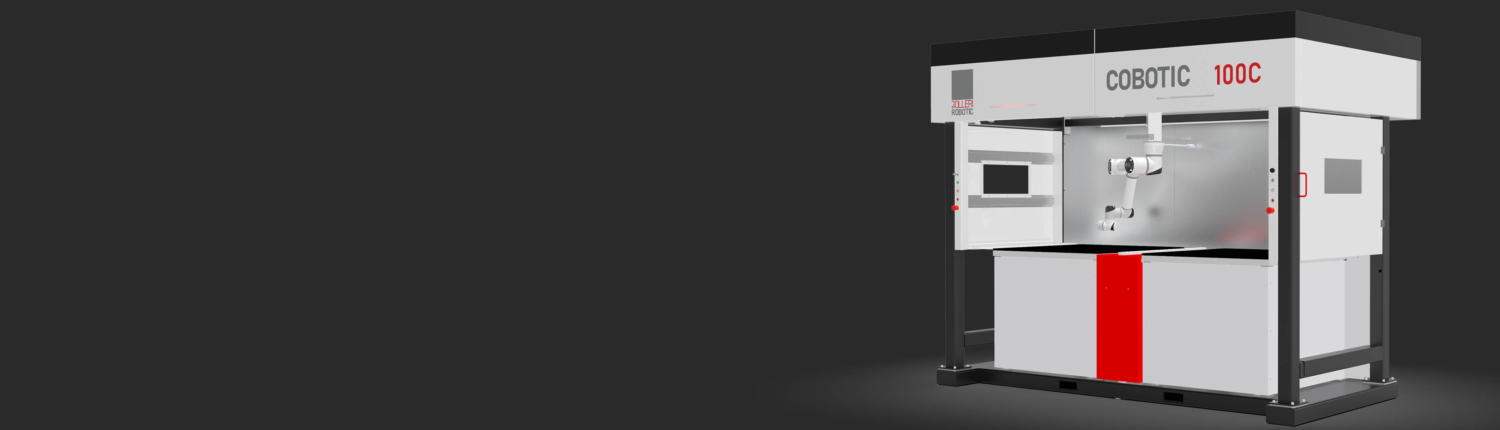

CLEANING ROBOT

Thanks to the cleaning machine COBOTIC 100C, programming activity is extremely easy and suitable for small production batches too. The remarkable software developments allowed to simplify all programming activities with a significant reduction of programming time.

COBOTIC 100C is able to integrate perfectly with the software to control pressure and fluctuation of all necessary deburring or cleaning tools.

Improved ability to clean different shapes according to different surface finishing and material.

Sheet metal cleaning with the robotic cell COBOTIC 100C.

COBOTIC 100C can use power tools or pneumatic tools handled directly by the system, including the possibility to use fast-change tools: an actual fully automatic tool change.

SIMPLE USE

Operations are quick and easy thanks to the most important commands being positioned on head grip.

SHAPE-DETECTING SYSTEM

By setting a starting and finishing point, COBOTIC 100C can move autonomously and detect sheet metal deformation without any programming activity by the operator.

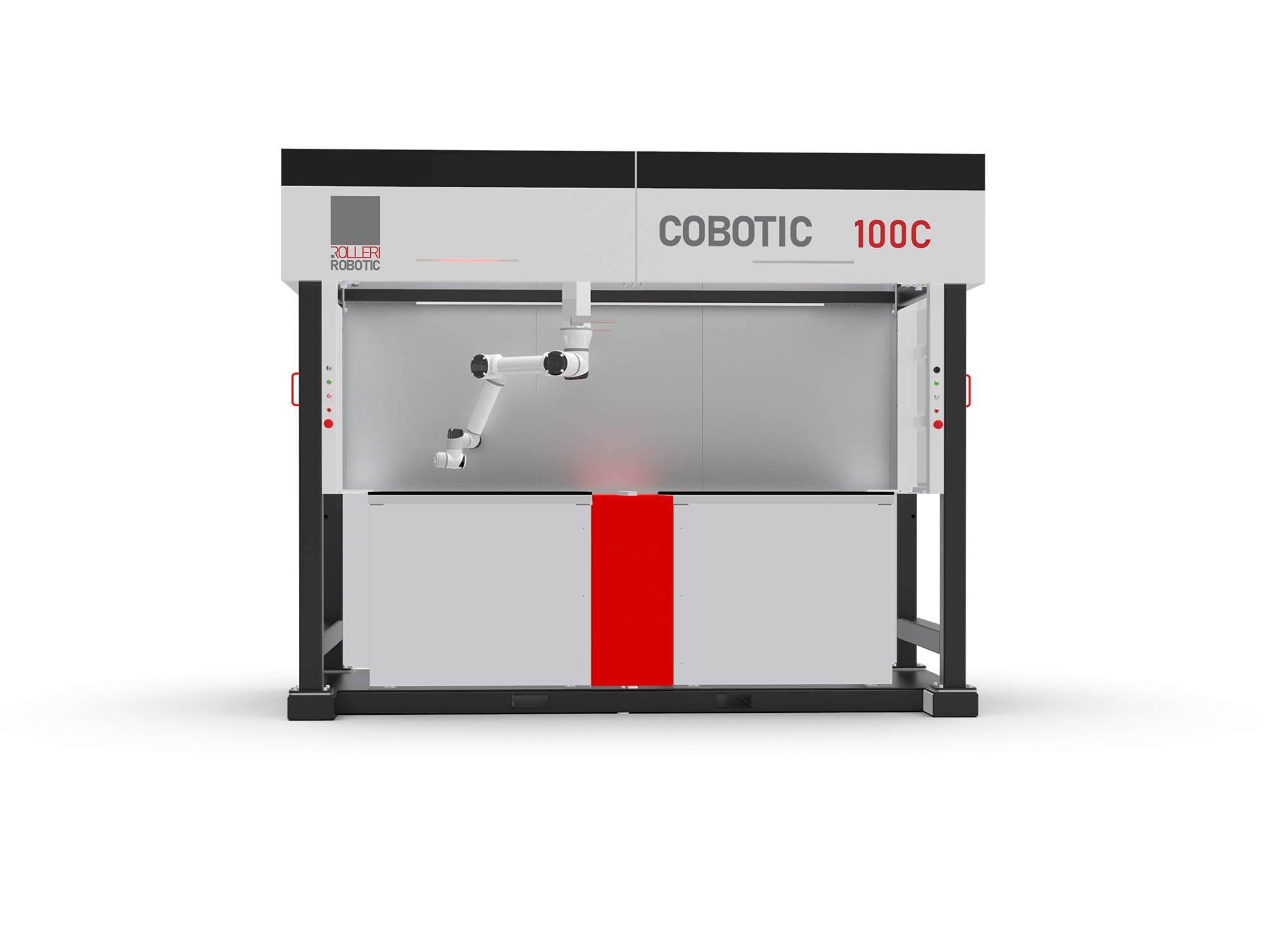

PRECISION +/- 0.03 mm

Cutting-edge technology thanks to the use of UR5e collaborative robot with 6 axes and 6 rotating DoF joints with +/-0.03mm precision and payload according to ISO 9283.

The machine control interface it’s really simple, buttons of program starting and stopping are really clear.

The touch screen control panel for programming and controlling the entire unit completes the equipment of COBOTIC 100C.

It is possible to set the starting point and the end point of the path but also to point the sheet metal through an extremely intuitive and fast command.

2. HANDLING

CLEANING ROBOT

The robotic cell structure has been designed for easy handling by forklift or crane, as it is composed of a unique part easy to be moved.

The forklift forks must be at least 90cm wide.

EASY HANDLING

It is possible to configure and re-configure the layout of the production lines within the production area in an extremely agile way.

4. TECHNOLOGY

DEBURRING ROBOT

PREDICTIVE SERVICE AND MAINTENANCE

COBOTIC REMOTE

Platform for remote support with smart glasses and tablet for direct and real-time interface with the robotic cell.

Thanks to COBOTIC REMOTE System, service technicians can help the operator carrying out any operation and intervening to prevent any future machine breakdown.

- N. 1 plug CEE 220V 16A (power absorbition 600W)

- compressed air connection with ø 8mm hose

- Collaborative robot UR5e with 6 axes and 6 rotating DoF joints.

- ‘+/-0.03mm precision. 900 mm arm range.

- Maximum payload according to ISO 9283.

Cobotic 100C is the smart cell with automatic tool change: one working tool and 4 in storage. Thanks to the simplicity of the software is possible to optimize the use of different tools and keep the wear monitored.

In addition to the software control, COBOTIC 100C uses the SAFETYTOOLS system to ensure correct attachment and use of the chosen tool.

- COBOTIC has 6 axis on the robot and a 7th axis 1800 mm that works in synchrony and ensures maximum use of the robot arm, reducing the possibility of encumbrance.

- No frequent maintenance required.

- Vertical fume extraction systems with 2 or 4 cartridges with differentiated pressure modules.

- Synchronised positioner for rotation of 360 pieces, to be applied to the workbench.

- Catalogue with a wide range of tools for use on the quick coupling system.

7. VIDEO

DEBURRING ROBOT

Our clients

Rolleri Robotic

Via del Commercio 1/3

Loc. Cabina – 29020

Vigolzone (PC), Italy

Phone: +39 0523 870905

Email: info@rollerirobotic.com