1. FUNCTIONS

MIG WELDING CELL

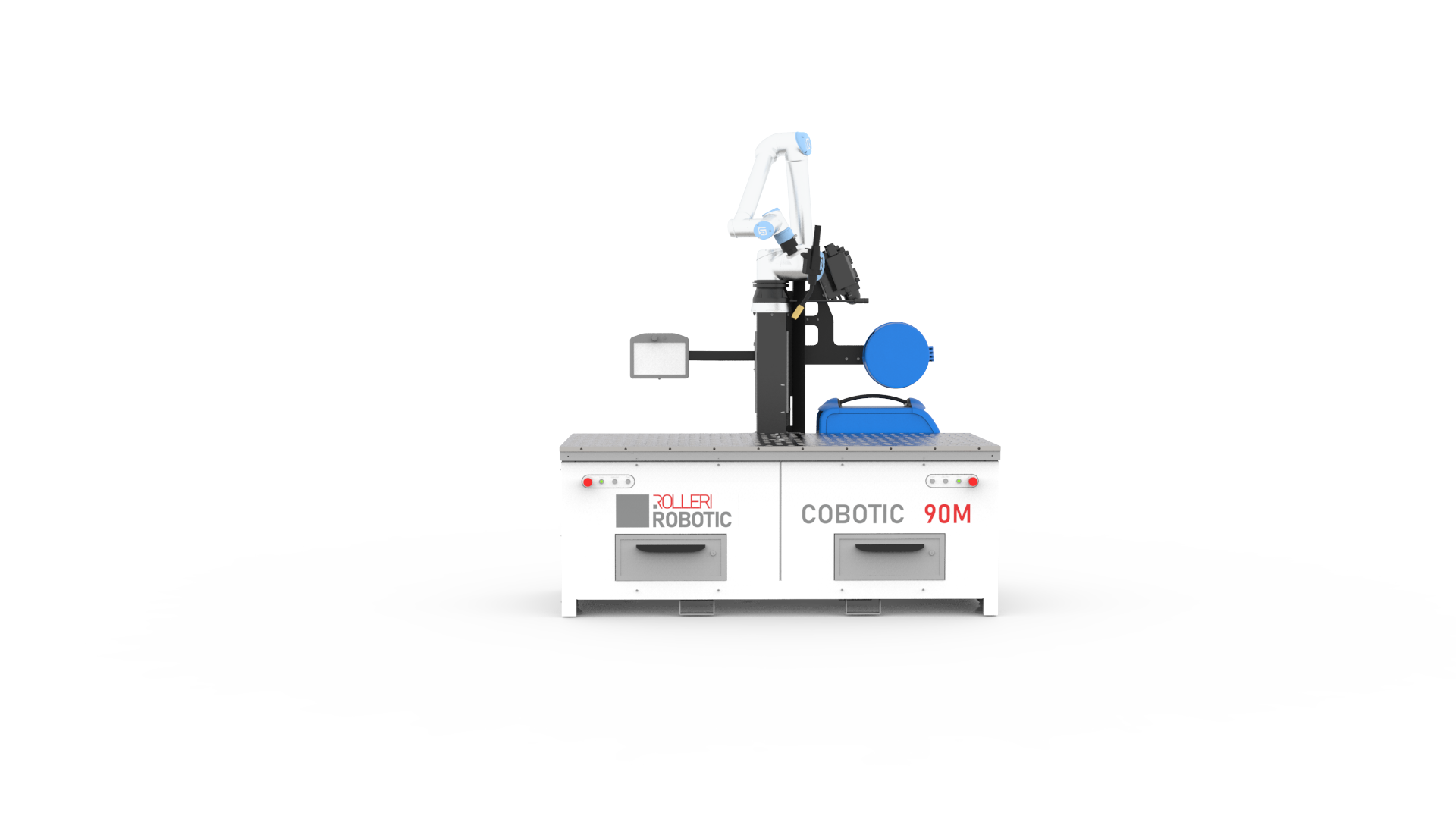

MIG welding – wire welding with robotic cell COBOTIC 90M.

Programming on platform.

With COBOTIC 90M programming activity is extremely easy and suitable for small production batches too. The remarkable software developments allowed to simplify all programming activities with significant reduction of programming time.

The COBOTIC 90M unit has the extraordinary ability to integrate perfectly with the software for controlling the oscillations of the torch and managing the welding wire.

SIMPLE USE

Operations are quick and easy thanks to the most important commands being positioned on the torch handle. By using these commands, you can indicate the starting and finishing point or point at the sheet metal.

SHAPE-DETECTING SYSTEM

By setting a starting and finishing point, can move autonomously and detect sheet metal deformation without any programming activity by the operator.

PRECISION +/- 0.1 mm

Cutting-edge technology thanks to the use of UR10e collaborative robot with 6 axes and 6 rotating DoF joints with +/-0.1mm precision and payload according to ISO 9283.

The machine control interface it’s really simple, buttons of program starting and stopping are really clear.

The touch screen control panel for programming and controlling the entire unit completes the equipment of COBOTIC 90M.

It is possible to set the starting point and the end point of the path but also to point the sheet metal through an extremely intuitive and fast command.

2. HANDLING

MIG WELDING CELL

COBOTIC 90M structure has been designed for easy handling by forklift or crane, as it is composed of a unique part easy to be moved.

The following system can be used for unloading and positioning the machine:

- Pick-up point with forklift with a capacity of not less than 25 q.

- The size of the forks must not exceed 150mm X 50mm, with a minimum length of 110cm.

EASY HANDLING

It is possible to configure and re-configure the layout of the production lines within the production area in an extremely agile way.

4. TECHNOLOGY – INDUSTRY 4.0

MIG WELDING CELL

REMOTE ASSISTANCE CONNECTION

COBOTIC 90M must be connected to an Internet network.

Connecting to the Internet can be done in several ways:

- With RJ45 network cable (strongly recommended for remote assistance)

- Possibility of Wi-Fi connection

- SIM card

The customer must associate the machine with an

IP address which he must then communicate.

- N.1 pneumatic connection operating pressure not lower than 7 bar consumption 10MI/min (the cell

is equipped with standard quick connection AT023401 PROF. GERMANY MALE 1/4) - MIG welding torch diameter 0.6 suitable for stainless steel machining.

- N. 1 industrial standard male 400VAC 16A 3P+N 50HZ connection. – ABSORPTION: 10.4 KW

- N. 1 industrial standard 230VAC 50HZ 2P+E male connection. – ABSORPTION: 1.5 KW

- N.1 connections for 100mm diameter hoses. – ABSORPTION: 2000 m3/h

- N.1 Fitting for pipes with a diameter of 9mm or 11.5mm and mixture suitable for the type of

welding.

- Collaborative robot UR10e 6 axes and 6 rotating DoF joints.

- +/- 0,1mm. precision.

- Maximum payload according to ISO 9283.

The system is fully integrated with MIG welding generator

TIG welding of all materials:

▪ Carbon steel ▪ Stainless steel ▪ Duplex steel ▪ Aluminium ▪ Copper ▪ Hard-facing

-

Predisposition torch MIG/MAG U/D

-

Predisposition torch PUSH/PULL

-

Predisposition Remote control RC

-

Predisposition Rapideep 2.0

-

Predisposition QuickPulse 2.0

-

Predisposition EN 1090 Program

-

Prediposition WeldNet System

The welder has a cooling system in order to guarantee 24/7 working.

Our clients

Rolleri Robotic

Via del Commercio 1/3

Loc. Cabina – 29020

Vigolzone (PC), Italy

Phone: +39 0523 870905

Email: info@rollerirobotic.com