1. FUNCTIONS

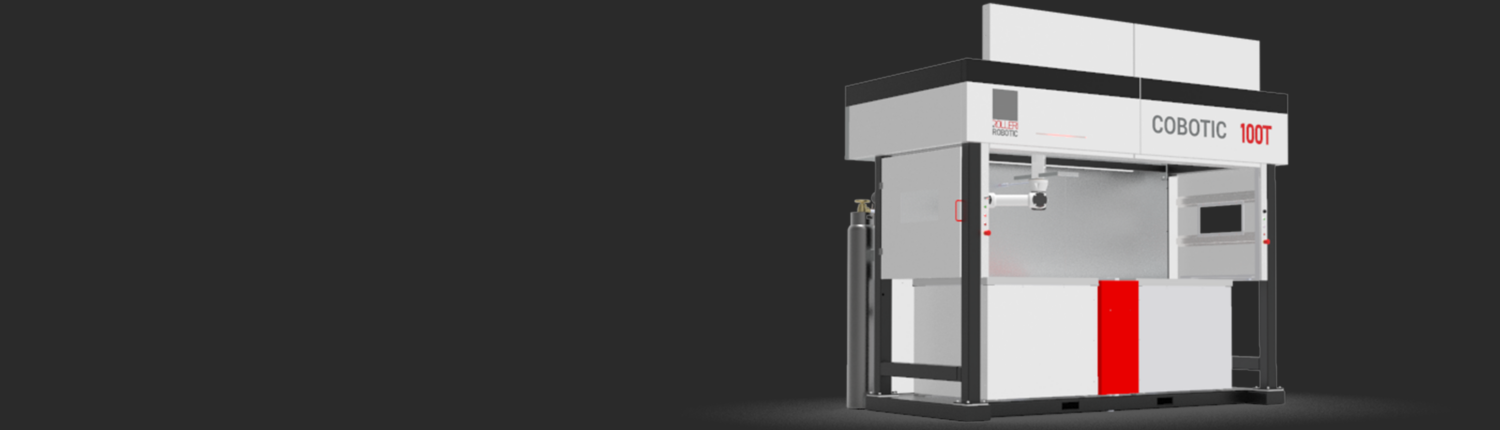

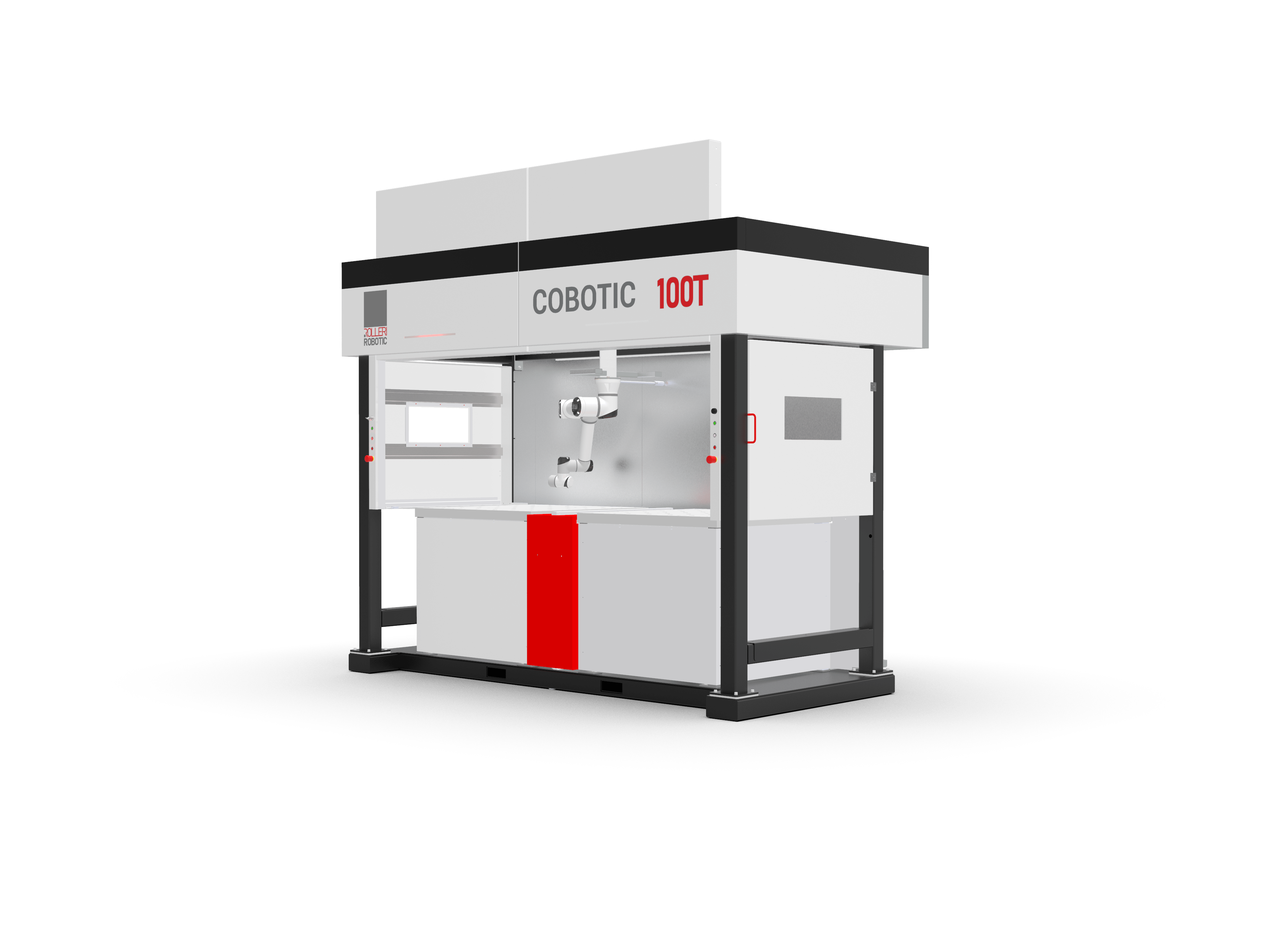

TIG WELDING CELL

TIG welding with robotic cell COBOTIC 100T.

Programmin on platform.

With COBOTIC 100t programming activity is extremely easy and suitable for small production batches too.

The remarkable software developments allowed to simplify all programming activities with 80% reduction of programming time.

SIMPLE USE

Operations are quick and easy thanks to the most important commands being positioned on the torch handle. By using these commands, you can indicate the starting and finishing point or point at the sheet metal.

4. TECHNOLOGY

TIG WELDING CELL

PREDICTIVE SERVICE AND MAINTENANCE

AI.LAND CLOUD

COBOTIC 100T is equipped with a computer connected to web platform AI.land cloud.

The machine is connected to the internet through the company network or through a mobile wireless connection that makes it extremely robust against cyber attacks.

COBOTIC REMOTE

Platform for remote support with smart glasses and tablet for direct and real-time interface with the robotic cell.

Thanks to COBOTIC REMOTE System, service technicians can help the operator carrying out any operation and intervening to prevent any future machine breakdown.

When you wear the smart glasses, service technicians can intervene to solve any technical or mechanical problem of the robotic cell or any practical problem related to welding (or other) operation carried out. The robotic cell undergoes ongoing monitoring of all its components.

The robotic cell undergoes ongoing monitoring of all its components.

- N. 1 plug CEE 380V 16A four-pole (power absorption 10 kW)

- N. 1 compressed air connection with ø 8mm hose

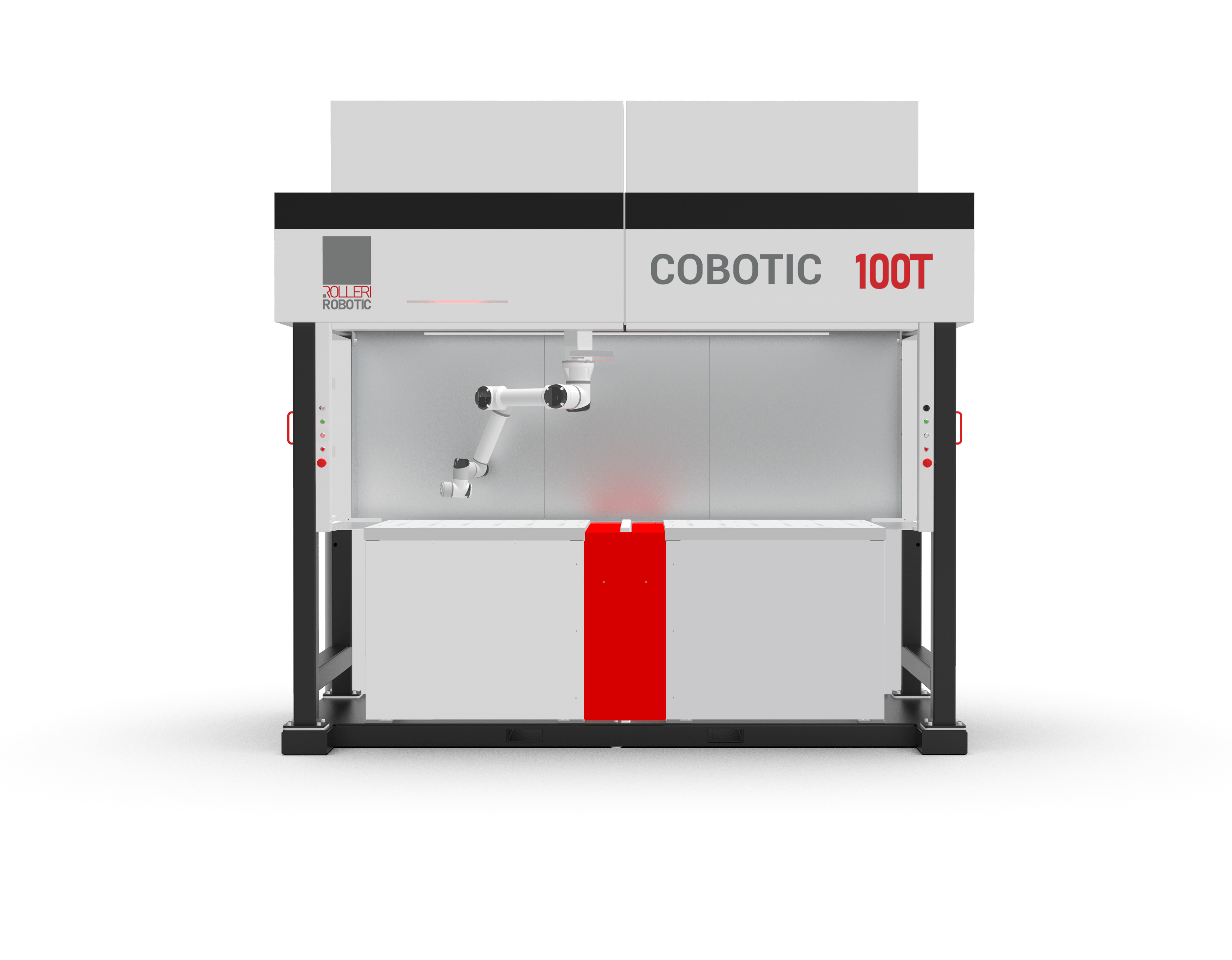

- Collaborative robot UR5e with 6 axes and 6 rotating DoF joints.

- +/-0.03 mm precision. 900 mm arm range.

- Maximum payload according to ISO 9283.

The system is fully integrated with

TIG welding generator (Voestalpine Bohler SELCO)

URANOS 2700 AC/DC EASYARC-3X400V-LCD 3,5.

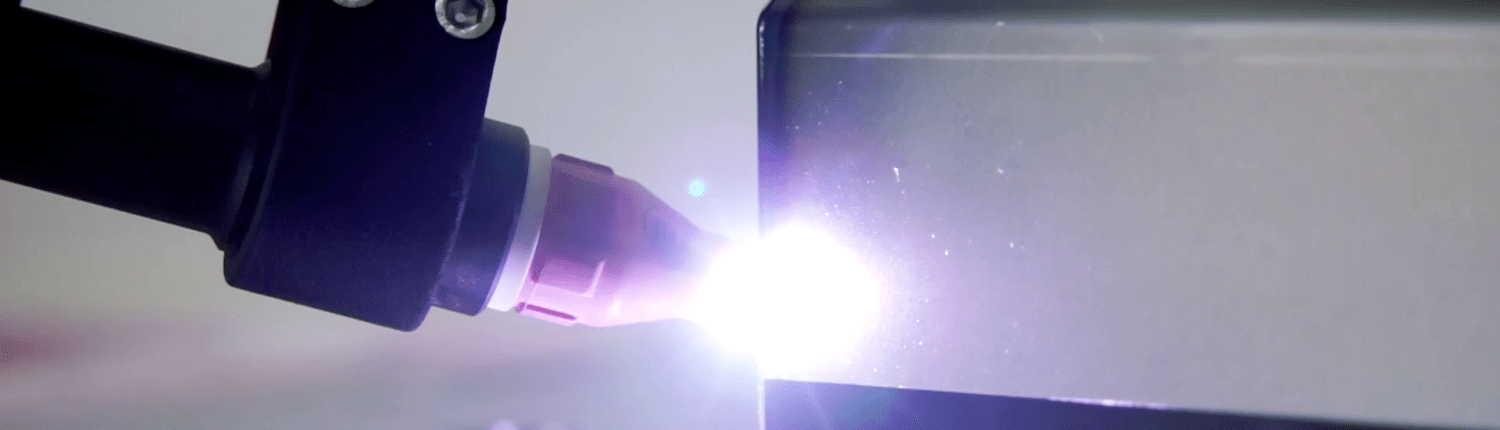

TIG welding of all materials:

▪ Carbon steel ▪ Stainless steel ▪ Aluminium ▪ Nickel ▪ Cast iron ▪ Copper ▪ Titanium

-

COBOTIC has 6 axis on the robot and a 7th axis 1800 mm that works in synchrony and ensures maximum use of the robot arm, reducing the possibility of encumbrance.

-

No frequent maintenance required.

-

Insertion of the 8th and 9th axis regulating the height of the worktop.

-

Vertical fume extraction systems with 2 or 4 cartridges with differentiated pressure modules.

-

Synchronised positioner for rotation of 360 pieces, to be applied to the workbench.

-

Possibility to weld with filler rod in a controlled way and with consumption control.

7. VIDEO

TIG WELDING CELL

Our clients

Rolleri Robotic

Via del Commercio 1/3

Loc. Cabina – 29020

Vigolzone (PC), Italy

Phone: +39 0523 870905

Email: info@rollerirobotic.com